Vestas MTSC237P1-03 Connection Rod

Detailed Description

Innovative Design, Robust and Efficient! Morteng Technologies introduces a new generation of wind turbine connecting rod solutions

In wind power generation systems, connecting rods are key components that ensure structural stability and transmit the power of the wind turbine. With the development of larger wind turbines, the strength and reliability of connecting rods directly affects the safety and efficiency of wind turbines.With more than 20 years of experience in the wind power industry, Morteng Technologies has launched a high-performance connecting rod system to provide safer and more durable solutions for the wind power industry!

Core Advantages of Morteng wind power connecting rod

High strength material: special alloy steel or composite material is used, which has excellent tensile and compressive properties, and adapts to high wind speeds and extreme weather conditions.

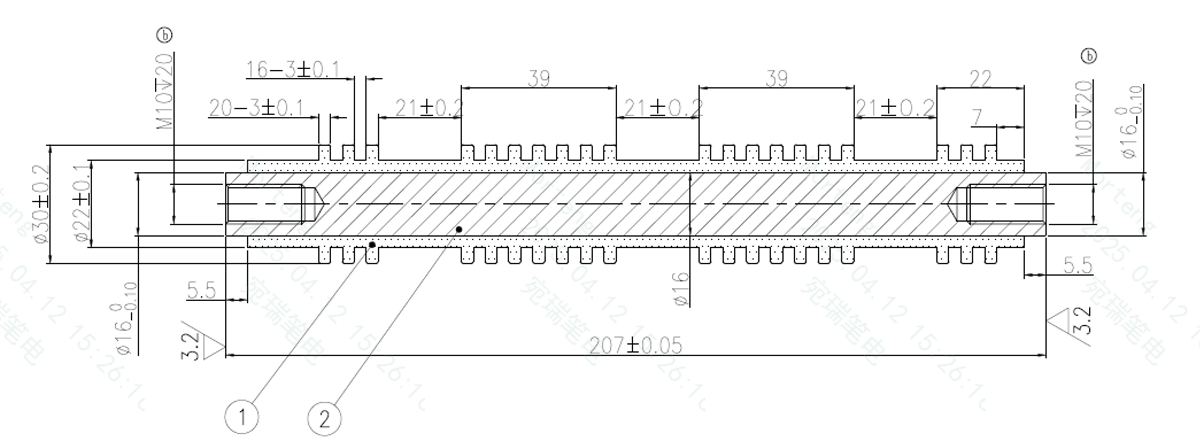

Modular design: Segmented connecting structure for easy transportation and installation, meanwhile, double reinforcement by thread locking + pin fixing prevents bolt loosening and improves tower stability.

Intelligent monitoring optional: integrated stress sensors, real-time monitoring of connecting rod stress state, early warning of structural fatigue, reducing maintenance costs.

Anti-corrosion and weather resistance: the surface is coated with C4 grade anti-corrosion coating, which is suitable for offshore wind power and other high salt spray environments, prolonging the service life.

Why Morteng?

Global application: The product is suitable for 2MW-10MW wind turbines and has been successfully applied in many wind power projects.

Customized service: Supporting individual requirements for different lengths, loads and connection methods.

Full process support: Provide full life cycle technical support from design, testing to installation.

Global Application Verification

products are suitable for a wide range of wind turbines and have been exported to many countries and regions, with more than 100,000 hours of stable operation.