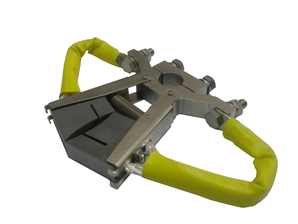

Vestas 753347 Brush Holder Assembly

Detailed Description

In the wave of global green energy transition, wind power industry, as an important part of renewable energy, is ushering in unprecedented development opportunities. However, the efficient operation of wind power equipment cannot be achieved without the support of key components, among which the brush holder, as the core component of the wind turbine collector ring system, directly affects the stability and power generation efficiency of the equipment. Mortengg, with its leading technical strength and rich experience in the industry, has launched the 753347 brush holder, which has injected new vitality into the wind power industry.

Technical advantages of 753347 brush holder

753347 brush holder is a high-performance product customized for wind power industry by Morteng Technology with the following technical advantages:

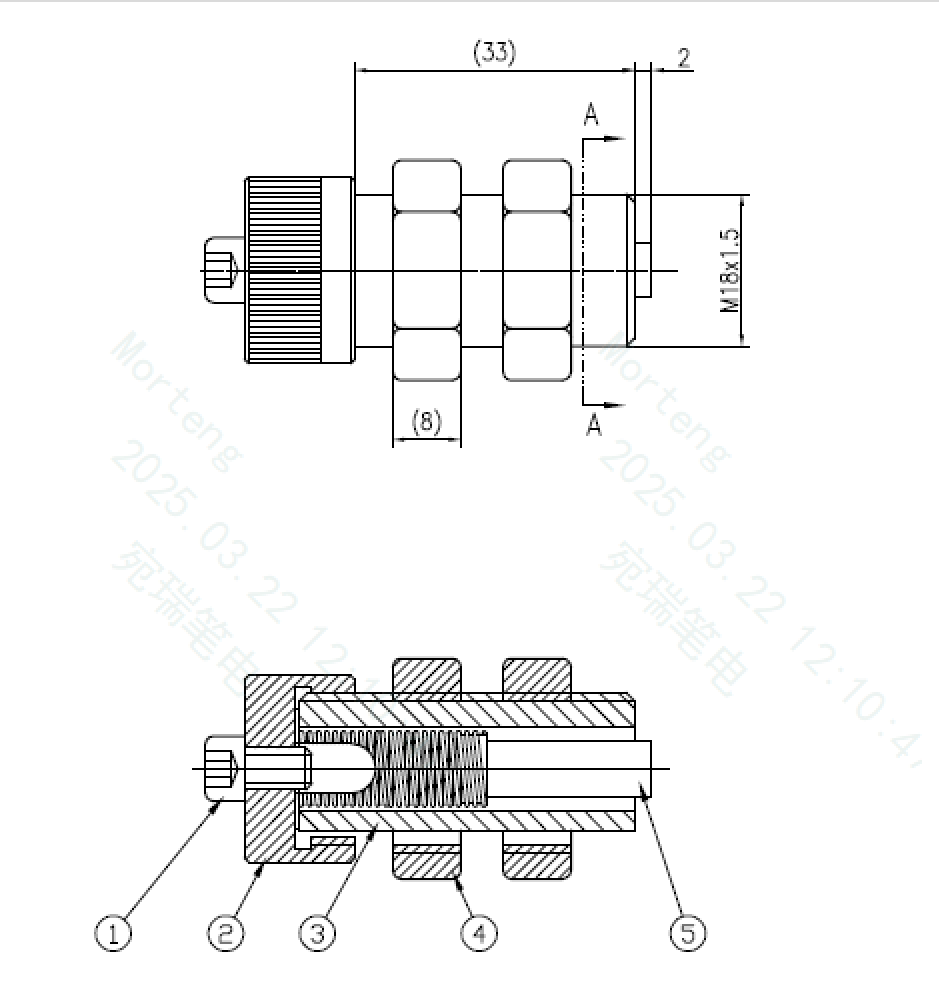

1. High stability design: Adopting unique insulated strut and double-padded cylinder structure to ensure the stability of the brush holder in the high-speed rotating environment and reduce the equipment failure rate.

2. convenient installation and maintenance: through modular design and optimized installation process, 753347 brush holder can be installed in a short time, significantly reducing maintenance costs.

3. Long life and high performance: The use of high-quality carbon brush material prolongs the service life and improves the efficiency of current transmission, which helps wind turbines to generate electricity efficiently.

753347 Brush Holder Market Application and Customer Feedback

753347 brush holders have been successfully applied in many large-scale wind farm projects, and customer feedback shows that:

Failure rate significantly reduced: a wind farm in the use of 753347 brush holder, equipment failure rate dropped by 30%.

Energy generation efficiency improvement: another customer feedback, brush holder replacement, wind turbine power generation efficiency increased by 15%.

Maintenance cost saving: The modular design shortens the maintenance time by 50% and significantly reduces the labor cost.