Pantongraph MTTB-C350220-001

Product Introduction

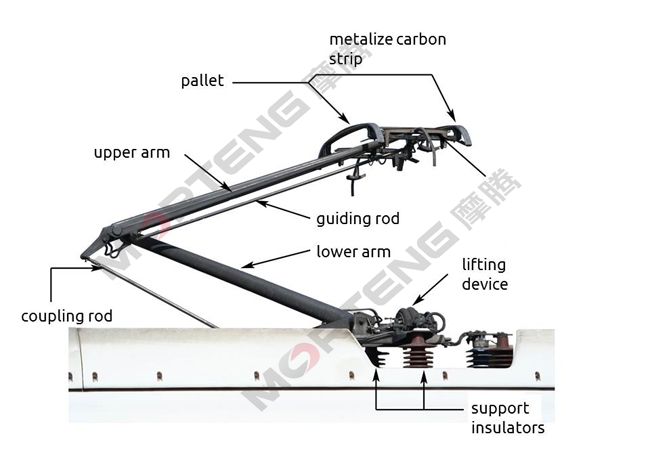

The electric transmission system for modern electric rail systems consists of an upper, weight-carrying wire (catenary). The pantograph is spring-loaded and pushes a contact shoe up against the underside of the contact wire to draw the electricity needed to run the train. The steel rails of the tracks act as the electrical return. As the train moves, the contact shoe slides along the wire and can set up acoustical standing waves in the wires which break the contact and degrade current collection.

Pantographs with overhead wires are now the dominant form of current collection for modern electric trains。

Pantographs are typically operated by compressed air from the vehicle’s braking system, either to raise the unit and hold it against the conductor or, when springs are used to effect the extension, to lower it. As a precaution against loss of pressure in the second case, the arm is held in the down position by a catch. For high-voltage systems, the same air supply is used to “blow out” the electric arc when roof-mounted circuit breakers are used.

Pantographs may have either a single or a double arm. Double-arm pantographs are usually heavier, requiring more power to raise and lower, but may also be more fault-tolerant.

Morteng offer quality pantograph products with international standard:

Product Description

|

Technical specifications |

||||

|

Parameter |

Numeric value |

|

Parameter |

Numeric value |

|

Shore hardness |

60~90HS |

20°C resistivity |

≤12 mH.m |

|

|

Bonding resistors |

≤5MΩ |

Impact toughness |

≥0.2J/cm2 |

|

|

Flow continuity |

≥20 L/min |

Flexural strength |

≥60MPa |

|

|

Carbon strip density |

≤2.5g/cm2 |

compressive strength |

≥140MPa |

|

|

Mechanical technical indicators |

|

Electrical specifications |

||

|

parameter |

Data |

parameter |

Data |

|

|

Speed range |

1000-2050rpm |

power |

/ |

|

|

Operating temperature |

-40℃~+125℃ |

Rated voltage |

/ |

|

|

Dynamic balance level |

Configurable according to customer's choice |

Rated current |

Configurable according to customer's choice |

|

|

Usage environment |

Sea-based, plain, plateau |

Withstand voltage test |

Up to 10KV/1min test |

|

|

Anti-corrosion rating |

Configurable according to customer's choice |

Signal cable connection method |

Normally closed, series |

|

Should you have any demand for slip ring system and component , please feel free to contact us, email : Simon.xu@morteng.com