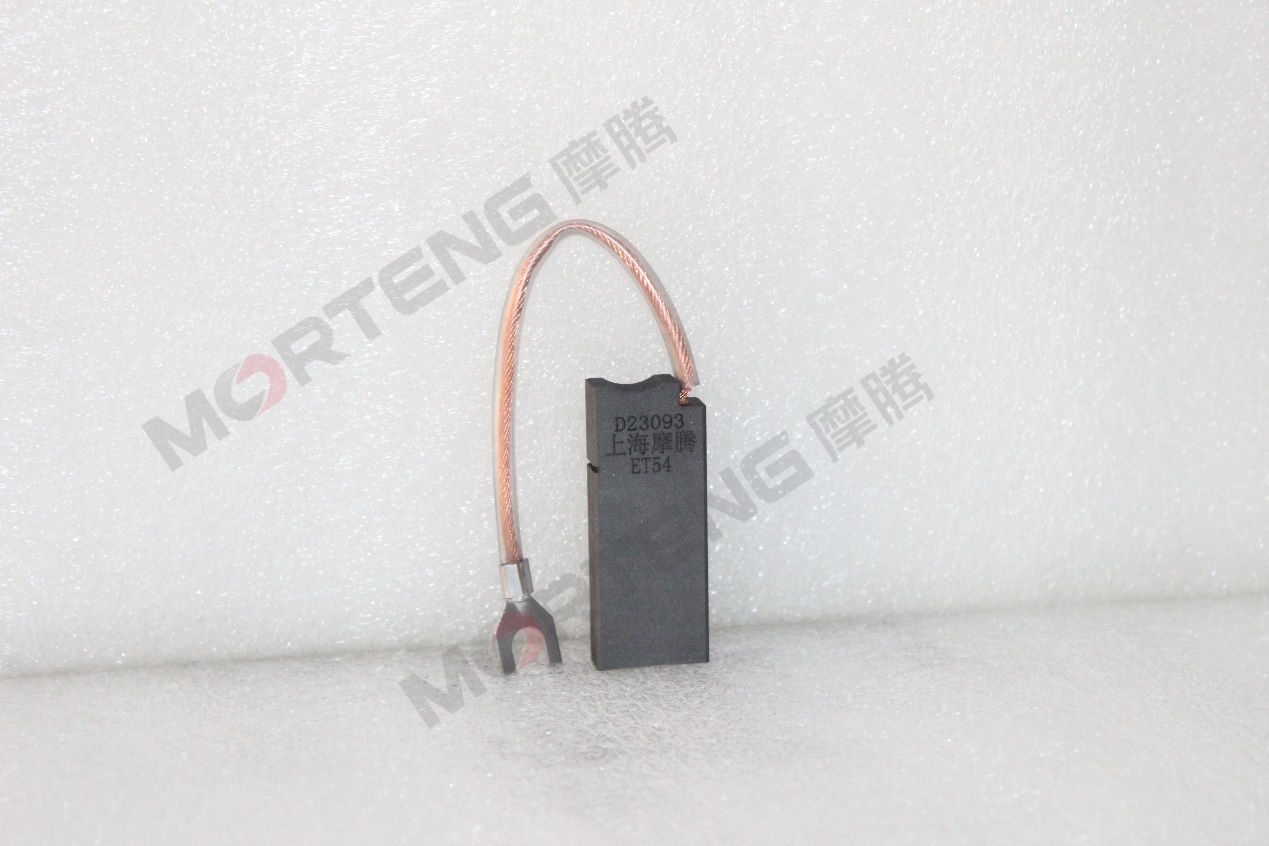

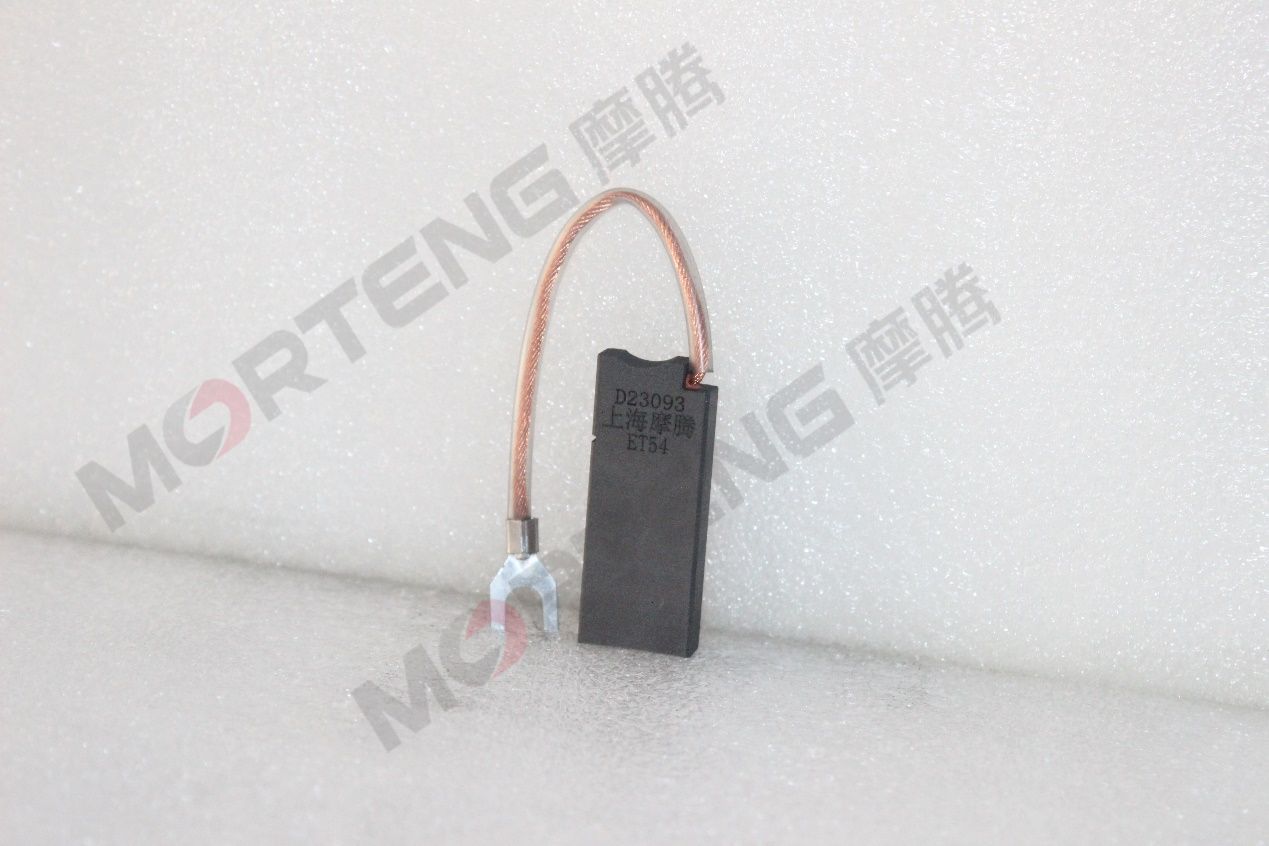

Wind Power Grounding Carbon Brush

Product Description

1. Convenient installation and reliable structure.

2. Good lubricity, suitable for high speed conditions.

3. Electrochemical graphite material has better vibration filter shape and is suitable for large vibration conditions.

4. Suitable for large current transmission, can meet most shaft grounding conditions.

Technical Specification Parameters

|

Grade |

Resistivity (μΩ·m) |

Bulk Density (g/cm3) |

Flexural Strength (Mpa) |

Hardness |

Nominal Current Density |

Circumferential Velocity (m/s) |

|

ET54 |

18 |

1.58 |

28 |

65HR10/60 |

12 |

50 |

For further questions or detailed options, please contact our experts for suggestions.

|

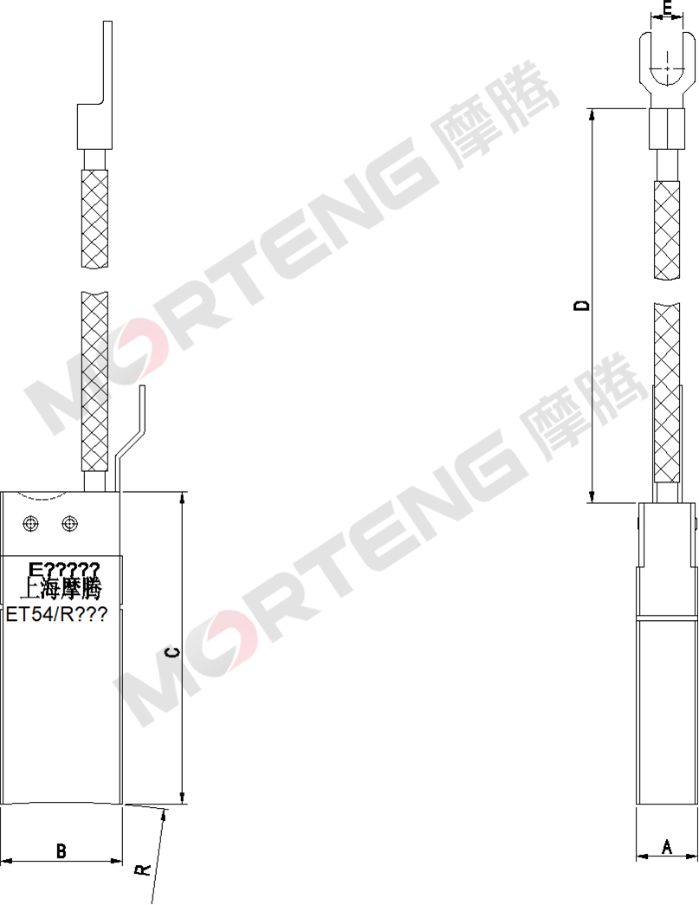

Basic dimensions and characteristics of carbon brush |

|||||||

|

Part number |

Grade |

A |

B |

C |

D |

E |

R |

|

MDFD-E125250-211-01 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R80 |

|

MDFD-E125250-211-03 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R85 |

|

MDFD-E125250-211-05 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R100 |

|

MDFD-E125250-211-10 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R130 |

|

MDFD-E125250-211-11 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R160 |

|

MDFD-C125250-135-44 |

ET54 |

12.5 |

25 |

64 |

140 |

6.5 |

R175 |

|

MDFD-C125250-135-20 |

ET54 |

12.5 |

25 |

64 |

120 |

6.5 |

R115 |

This brush we have standard type, and it can also be customized according to your need.

Non-standard Customization is Optional

Materials and dimensions can be customized, and the normal brush holders’ opening period is 45 days, which takes a total of two months to process and deliver the finished product.

The specific dimensions, functions, channels and related parameters of the product shall be subject to the drawings signed and sealed by both parties. If the above mentioned parameters are changed without prior notice, the Company reserves the right of final interpretation.

Main advantages:

Rich carbon brush manufacturing and application experience

Advanced research and development and design capabilities

Expert team of technical and application support, adapt to various complicated working environment, customized according to customer's specific requirements

Better and overall solution, less commutator wear and damage

Lower motor repair rate

The function of the carbon brush is to transmit electric power or signals between fixed and rotating parts. This can occur within a wide range of applications in different operational conditions, all of which have special requirements.