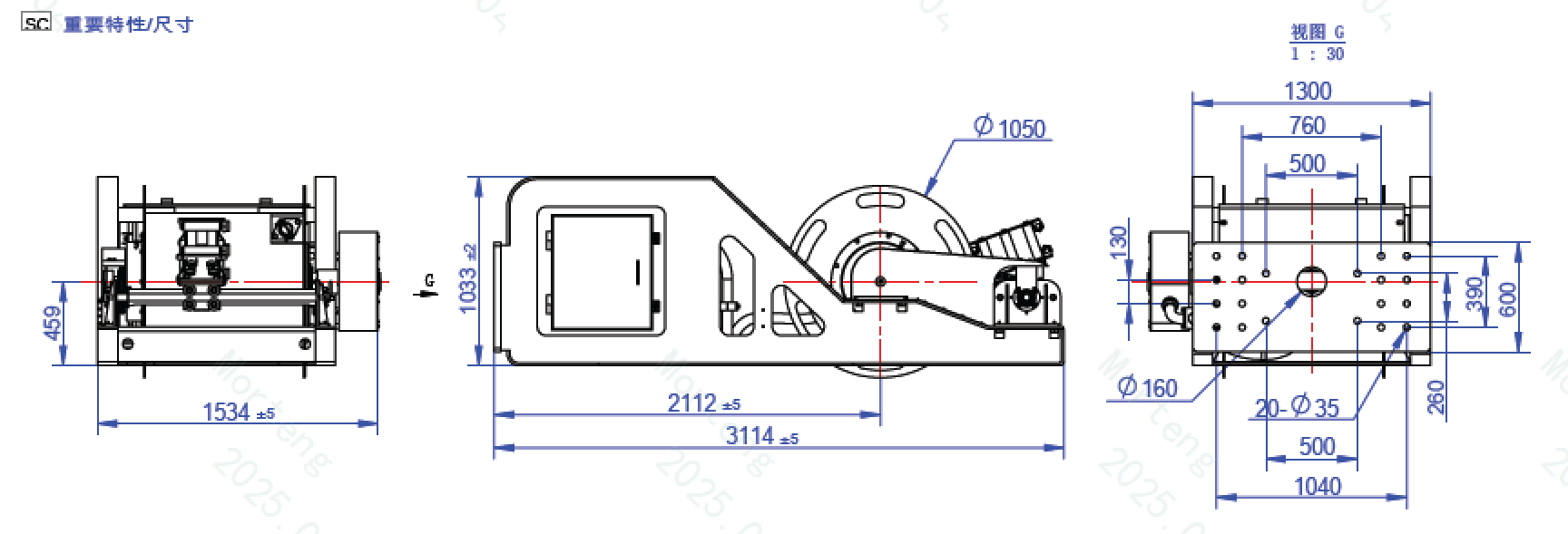

Spring Cable Reel

Detailed Description

Morteng Vehicle-mounted Spring Reel System: Empowering Electric Construction Machinery with Autonomous Mobility

The Morteng system revolutionizes electric construction machinery by giving cables “autonomous awareness.” Its adaptive retraction logic is a marvel of engineering. Equipped with high - precision sensors, the system can detect the slightest movement of the equipment. Once in motion, the reel senses the direction of movement, and then the spring releases stored energy with millisecond - level response speed, allowing the cable to extend gracefully like a lively silk ribbon. When the equipment retreats, the energy - storing spring retracts the cable off the ground at a speed of up to 2 meters per second, forming a perfect “zero - intervention” operational loop. The three - dimensional protection mechanism, strengthened by a network of industrial - grade nylon - coated guide wheel sets, maintains a minimum clearance of 30 centimeters between the cable and the ground. This ensures that even on the most rugged terrains, abrasion and snagging are non - issues.

Three key innovations set Morteng apart. The bio - inspired spring system, modeled after tendon structures, is composed of dual - stage alloy springs with a tensile strength of over 1,500 MPa. These springs adjust force based on cable weight and terrain, ensuring optimal performance under any conditions. A fault self - diagnosis network, embedded with 128 micro - sensors, monitors over 20 system parameters in real - time. This proactive approach reduces unexpected downtime by up to 70%. The modular design, featuring quick - connect interfaces compliant with ISO standards, allows for easy installation on various equipment within 48 hours, minimizing disruption to operations.

For customers, Morteng solves major pain points. It eliminates 80% of cable wear, extending cable lifespan from an average of 2 years to 8 - 10 years, resulting in significant cost savings. By automating cable management, it frees up 1,500 hours of manual labor per year, which can be redirected towards more productive tasks. In a case study at a major wind farm, the installation of Morteng systems on turbine maintenance cranes increased operational efficiency by 35%. The system also unlocks full - directional mobility and offers a “turnkey” solution, covering everything from installation to 24/7 technical support. A port group’s data shows Morteng - equipped cranes can move 6 km daily, with flexibility matching fuel models and zero nighttime noise complaints.

Morteng’s philosophy focuses on reducing energy loss from cable friction, respecting human expertise, and enhancing system resilience. By liberating equipment from cable constraints, Morteng reshapes the human - machine relationship, turning operators into efficiency commanders. As the demand for sustainable and intelligent construction solutions grows, the Morteng system stands at the forefront, driving the industry towards a more efficient and eco - friendly future.