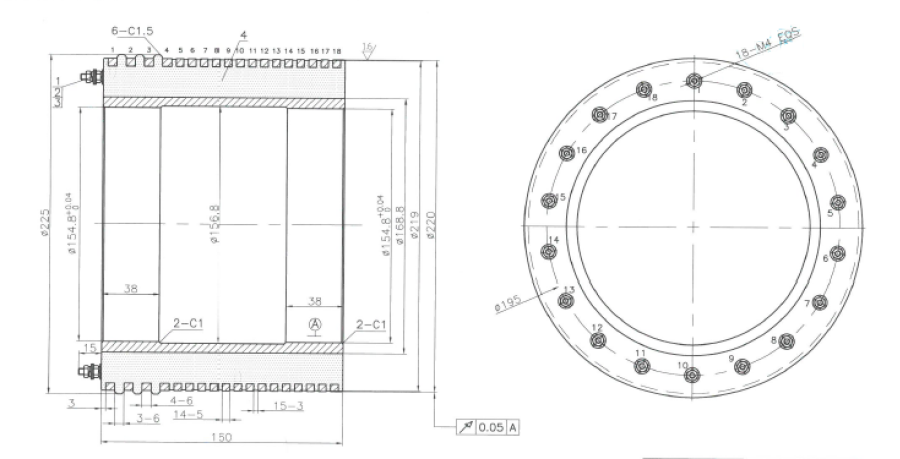

Slip Ring for Cable Equipment D219xI 154x160mm

Specifications

1. Insulation performance: Resistant to high voltage of 415V;

2. Coaxiality of the collector ring: φ0.05;

3. Unmarked chamfer: 0.5x45°;

4. Maximum rotational speed: 500 rpm

5. Linear tolerance not specified shall be processed in accordance with GB/T1804-m;

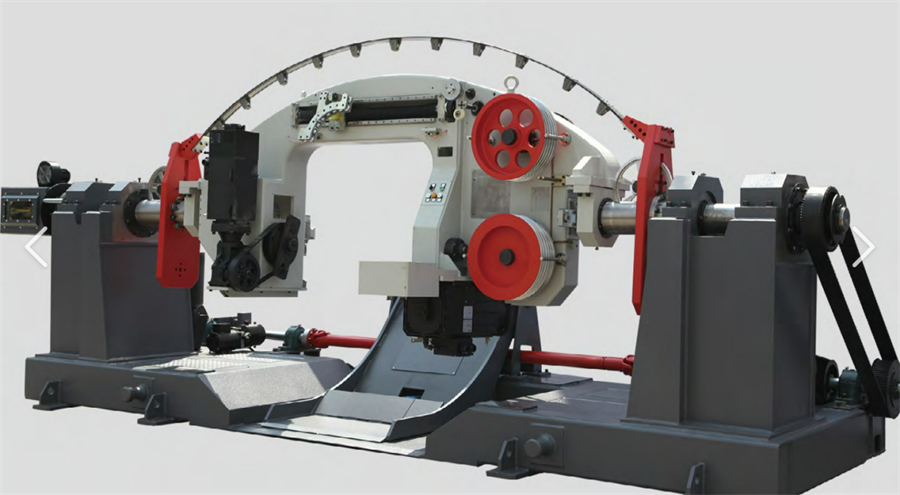

The Morteng 18 Ring is a core component in cable stranding equipment, serving as a key link for transmitting power, control signals, and electrical signals between the fixed frame and the rotating stranding die. In the cable stranding process, the continuous high-speed rotation of components such as stranding dies, stranding heads, and traction wheels is a core prerequisite for ensuring the stable structure of cables. The Morteng 18 Ring successfully breaks the constraints of traditional wiring, completely avoids problems such as cable tangling and pulling, and provides reliable support for the continuous operation of the production line.

The Morteng 18 Ring is meticulously crafted using high-purity oxygen-free copper, silver alloy contacts, and high-temperature resistant polytetrafluoroethylene (PTFE) insulating materials. It not only boasts excellent electrical conductivity due to its ultra-low contact resistance but also features strong wear resistance and anti-aging properties. Its special sealed structure design can effectively resist the adverse environmental impacts commonly found in cable production workshops, such as metal dust, cable oil contamination, and temperature-humidity fluctuations. Even under harsh working conditions of long-term and high-speed operation, it can maintain stable transmission performance, ensuring no signal delay or attenuation. Some high-end models of the Morteng 18 Ring are also integrated with electrical rotary joints, enabling simultaneous composite transmission of multiple electrical signals. This meets the high-precision control requirements in the stranding process, such as conductor tension monitoring and die speed feedback, further promoting the intelligent upgrading of stranding equipment.

In response to the specific requirements of cable stranding equipment, the Morteng 18 Ring plays an irreplaceable role in ensuring stranding precision. By providing stable power supply and real-time control signal transmission to the rotating stranding mechanism, it can accurately adjust the stranding angle and tension balance of each conductor bundle. This effectively reduces quality issues caused by unstable transmission, such as cable pitch deviation and conductor deformation, significantly improving the electrical performance and mechanical strength of finished cables. Whether applied in large-scale production lines for power cables and communication cables, or in customized production equipment for special cables, the Morteng 18 Ring is a core guarantee for improving stranding efficiency and reducing equipment failure rates.