Cement plant equipment Carbon Brush ET46X

Detailed Description

|

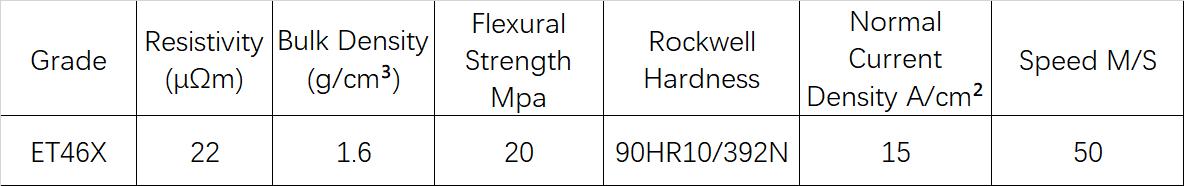

Basic Dimensions and Characteristics of Carbon Brushes |

||||||

|

Carbon Brush Drawing No. |

Grade |

A |

B |

C |

D |

R |

|

MDT11-M250320-016-19 |

J201 |

25 |

32 |

60 |

6.5 |

R140 |

|

MDT11-M250320-016-20 |

J201 |

25 |

32 |

60 |

6.5 |

R177.5 |

|

MDT11-M250320-016-21 |

J204 |

25 |

32 |

60 |

6.5 |

R140 |

|

MDT11-M250320-016-22 |

J204 |

25 |

32 |

60 |

6.5 |

R177.5 |

|

MDT11-M250320-016-23 |

J164 |

25 |

32 |

60 |

6.5 |

R140 |

|

MDT11-M250320-016-24 |

J164 |

25 |

32 |

60 |

6.5 |

R177.5 |

Brush Types

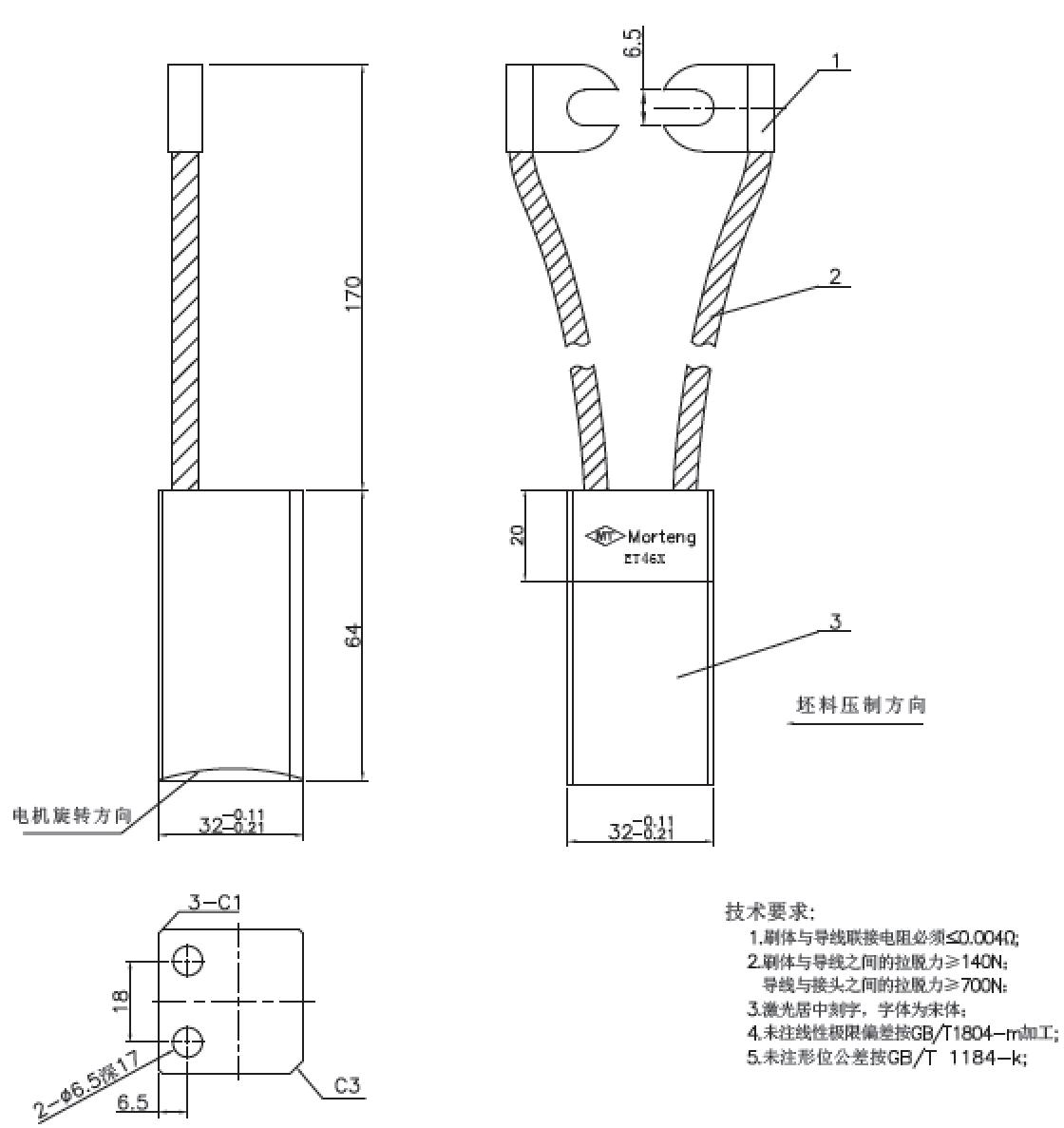

Morteng Cement Plant Carbon brush

Powering cement plants with next-gen reliability: Morteng’s cement plant carbon brushes redefine operational efficiency!

Engineered specifically for the grueling conditions of cement plants, Morteng’s carbon brushes stand out with exceptional wear resistance. Crafted from a high-grade composite material tailored for heavy-industry demands, they drastically reduce replacement cycles compared to standard alternatives. This extended service life translates directly to less unplanned downtime—critical for cement production lines where every minute of stoppage impacts output—and lowers long-term maintenance costs by cutting down on frequent part changes.

Stability is another cornerstone of our design. These brushes maintain consistent current transfer even amid the extreme temperatures, dust, and vibration common in cement manufacturing. The precision-machined contact surface minimizes sparking and ensures steady interaction with motor commutators, preventing premature wear on both the brush and the motor itself. This reliability is a game-changer for high-load applications like kiln drives and conveyor systems, where component failure can trigger costly production halts.

And when maintenance is needed, we’ve made it hassle-free. The tool-free quick-change mechanism allows your maintenance team to swap out brushes in just minutes, no complex disassembly required. This streamlined process keeps your equipment back online fast, maximizing operational uptime and keeping your production workflow running smoothly without unnecessary delays.Trust Molten’s legacy of industrial innovation for components that deliver durability, reliability, and efficiency. Upgrade your cement plant’s performance today!