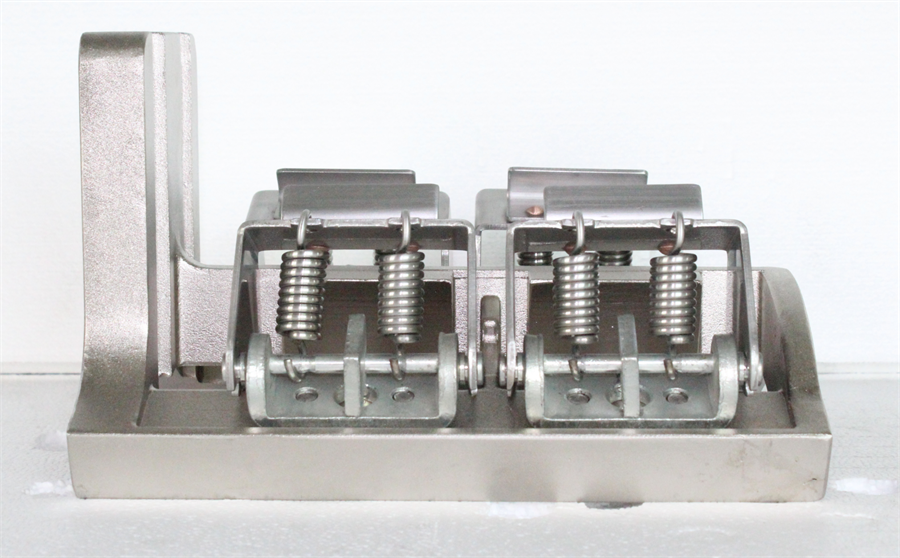

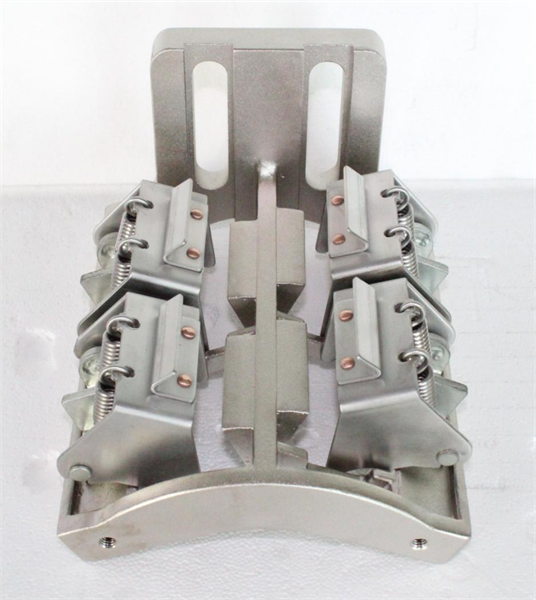

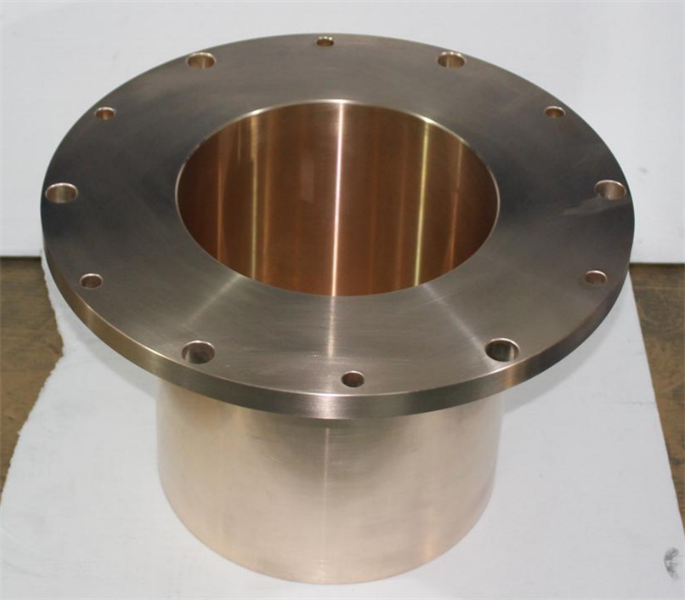

Brush Holder for Electroplating Machine

Detailed Description

Morteng Brush Holders for Electroplating Equipment: Engineered for Stability and Longevity In electroplating processes, maintaining a consistent and reliable electrical current is essential for achieving high-quality, uniform plating results. This current is transferred to the rotating workpiece via a slip ring and brush system, where the brush holder plays a critical role. Designed specifically for the challenging conditions of electroplating workshops, the Morteng brush holder ensures stable power transmission even in humid, corrosive, and vibration-prone environments. Its robust construction uses corrosion-resistant materials and protective coatings to withstand prolonged exposure to chemical fumes and moisture.

A key feature of the Morteng brush holder is its adjustable pressure mechanism, which allows precise control over the contact force between the carbon brush and the slip ring. This helps prevent issues such as arcing from insufficient pressure or accelerated wear from excessive force, thereby supporting consistent performance and extending service life. The holder’s side-mount design simplifies installation and maintenance, enabling quick brush replacement without major disassembly. For added operational security, an optional brush wear alarm can be integrated to provide early warning when brushes near the end of their life, helping to avoid unplanned stoppages and potential damage to the slip ring.

Understanding that electroplating equipment varies widely in design and requirement, Morteng also offers full customization—including non-standard sizes, mounting layouts, and material specifications—to ensure perfect compatibility with your system. By combining durable design, functional intelligence, and flexible configuration, the Morteng brush holder delivers a dependable solution that enhances plating quality, reduces maintenance effort, and supports continuous production efficiency.