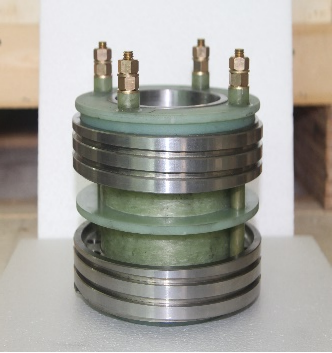

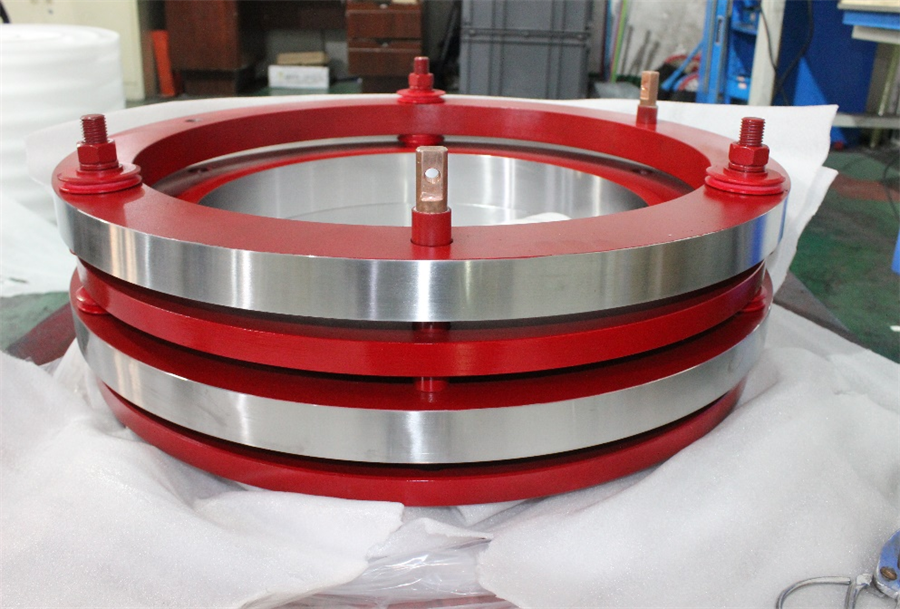

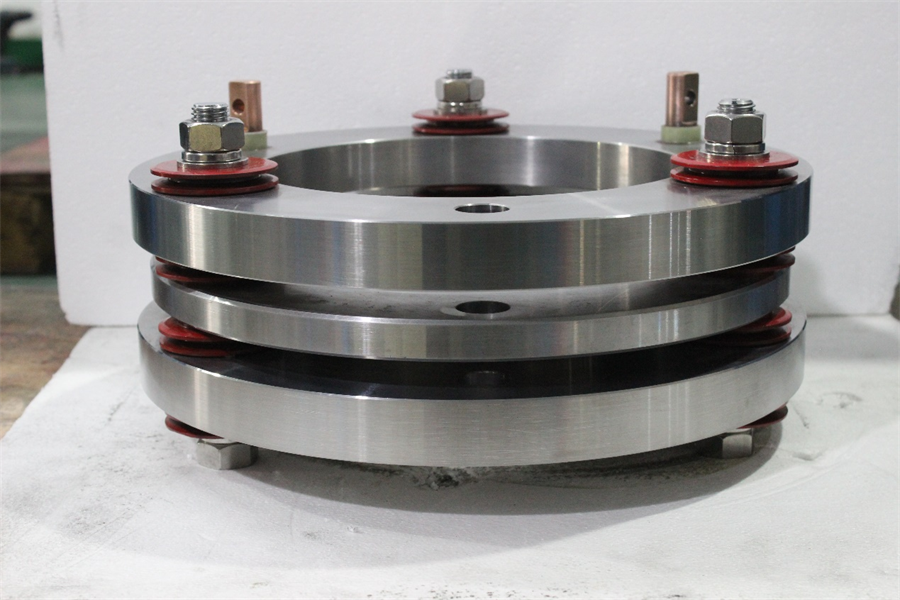

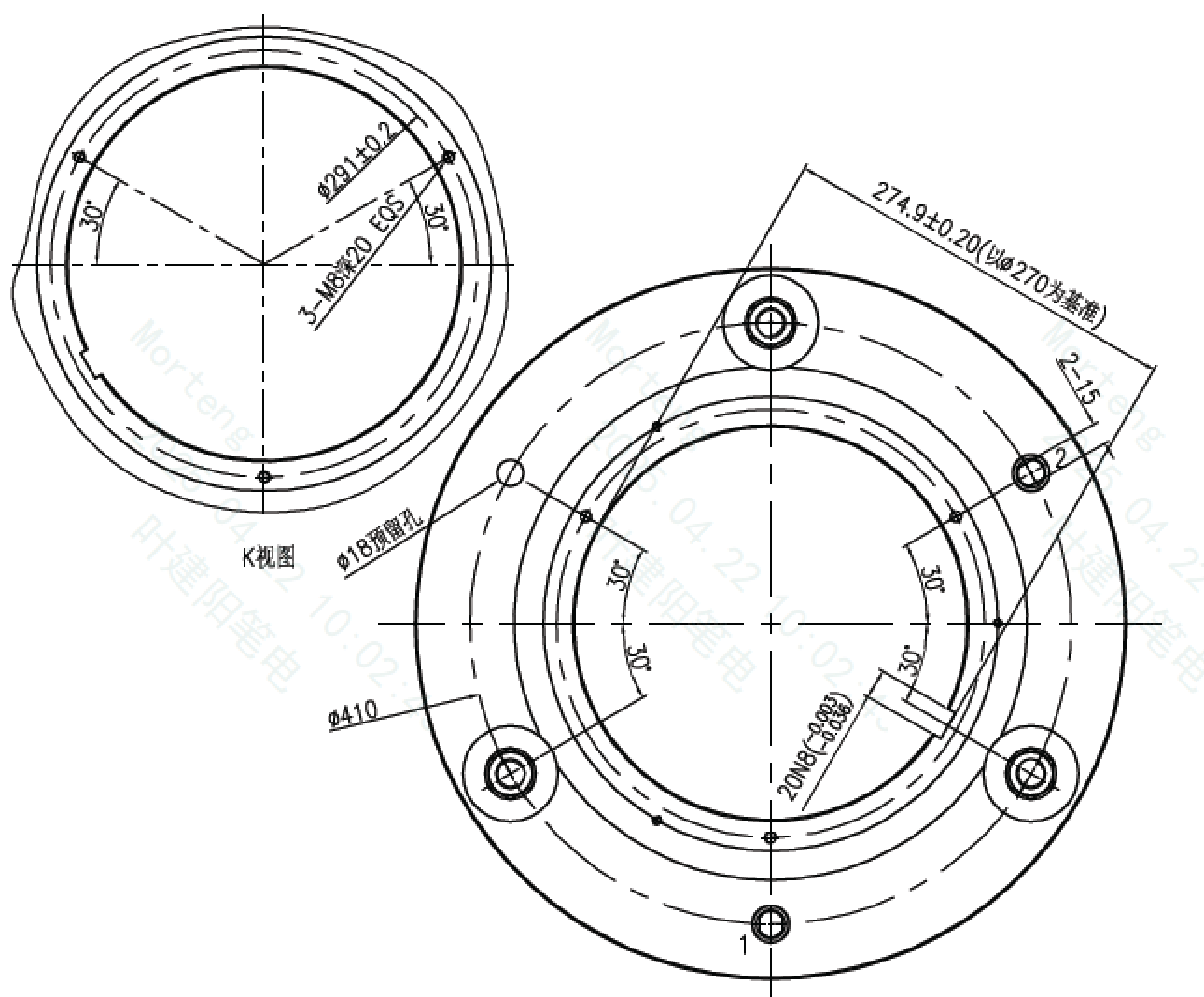

Slip Ring for Industrial Motor D485

Detailed Description

|

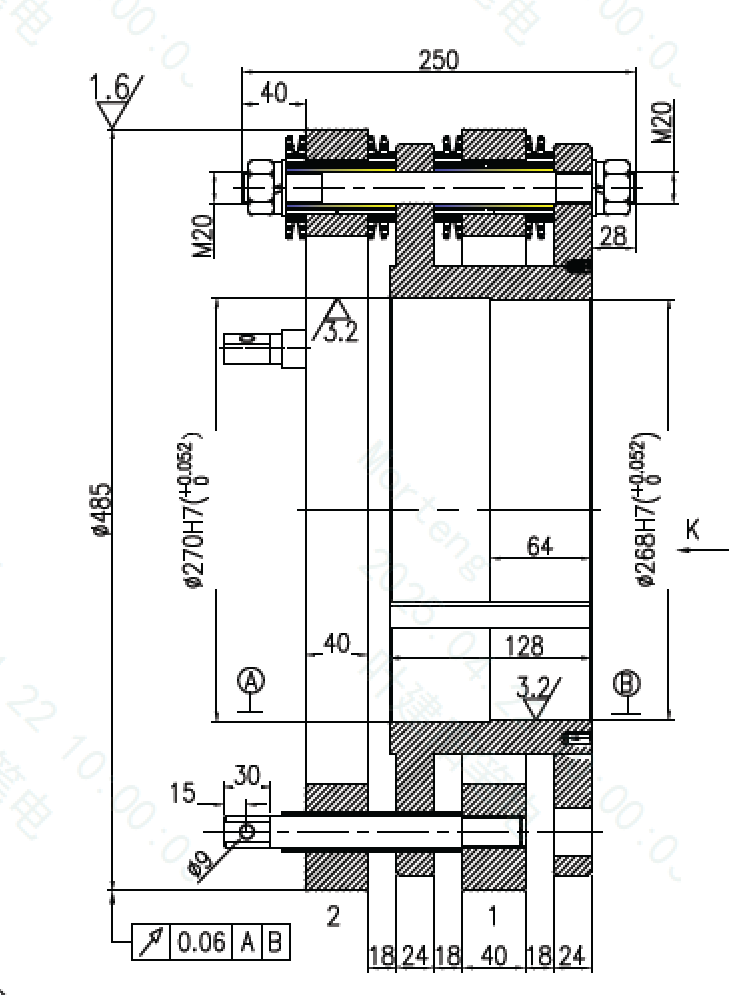

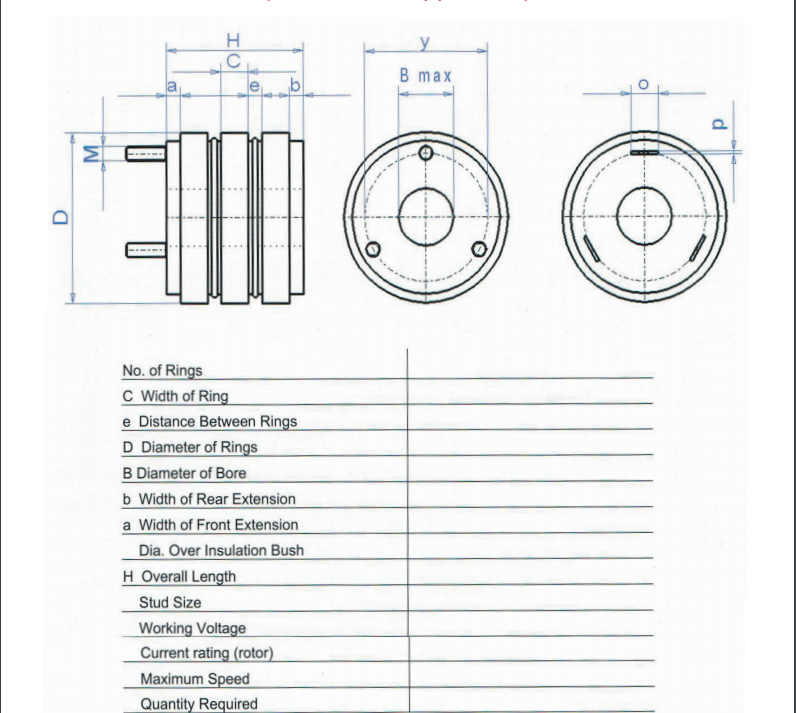

Overview of Basic Dimensions of Slip Ring System |

||||||

|

Dimension

|

OD |

ID |

Height |

Width |

Rod |

PCD |

|

MTA26802133-04 |

Ø485 |

Ø270 |

250 |

2-40 |

3-M20 |

Ø410 |

Product Main Features:

Stainless steel power slip ring for industrial motor

Small outside diameter, low linear speed and long service life.

Can be customized according to the user's needs

Variety of products, can be applied to different working conditions.

|

Mechanical Information |

Electric Information |

||

|

Parameter |

Value |

Parameter |

Value |

| Speed Range |

1000rpm |

Power |

/ |

| Working temperature |

-40℃~+125℃ |

Rated voltage |

42V |

| Dynamic balance grade |

G2.5 |

Rated current |

280A |

| Working conditions |

Sea base, plain, plateau |

Hi pot test |

5000V/1min |

| Corrosion grade |

C3、C4 |

Signal cable connection |

Normally closed, in series |

Non-standard customization options

Certificate

Since Morteng established in 1998, we has been committed to improving our own product research and development capabilities, improving product quality, offering high-quality service. Because of our firm belief and persistent efforts, we have obtained many qualification certificates and customers’ trust.

Morteng qualified with International certificates:

ISO9001-2018

ISO45001-2018

ISO14001-2015

Company Introduction

The company’s core products include carbon brushes for wind turbines, brush holders, slip ring assemblies, and stainless-steel constant pressure springs, which are widely used in wind power, thermal and hydropower generation, rail transport, aerospace, and marine industries. Its vertically integrated manufacturing capabilities ensure strict quality control, with materials engineered for high conductivity, wear resistance, and thermal stability. Moteng’s technological edge lies in material innovation, such as metal-graphite composites, and patented designs like the CT series slip rings, which have achieved domestic substitution for imported solutions .

With production facilities in Vietnam and offices across Europe, Mortengserves customers in over 30 countries. The company’s commitment to sustainability is reflected in its "Green Supplier Level 5" certification from Goldwind Science & Technology and its participation in renewable energy projects globally. In 2024, Mortengfurther expanded its footprint with a CNY 1.55 billion investment in a new production base for construction machinery slip rings and marine generator components, reinforcing its position as a key player in the global electrical carbon solutions market .