OEM manufacturer Dc Motor Carbon Brush Holder - EH702T Carbon brush for power plant – Morteng

OEM manufacturer Dc Motor Carbon Brush Holder - EH702T Carbon brush for power plant – Morteng Detail:

Influencing Factors

What will influence carbon brush performance?

Carbon brush pressure,

Current density, Motor speed,

Carbon brush material, Humidity,

Temperature, Polarity,

Rotor slip ring material, Chemical,

Oil pollutants

……

Product Description

|

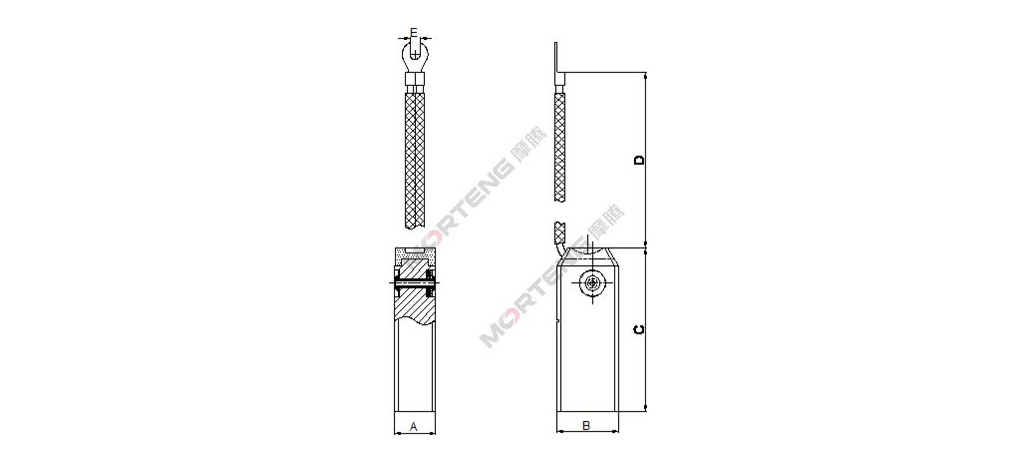

Basic Dimensions and Characteristics of Carbon Brush |

|||||||

|

Part Number |

Grade |

A |

B |

C |

D |

E |

R |

|

MDK01-N254381-081-07 |

EH702 |

25.4 |

38.1 |

102 |

145 |

6.5 |

|

|

Material Data |

|||

|

Bulk density (JB/T 8133.14) |

Shore hardness (JB/T 8133.4) |

Flexural strength (JB/T 8133.7) |

Specific electr. Resistance (JB/T 8133.2) |

|

1.32 g/cm3 |

18 |

7 MPa |

20μΩm |

Convenient installation and reliable structure,

Good lubricity,

The material has low resistivity and is suitable for transmitting large current.

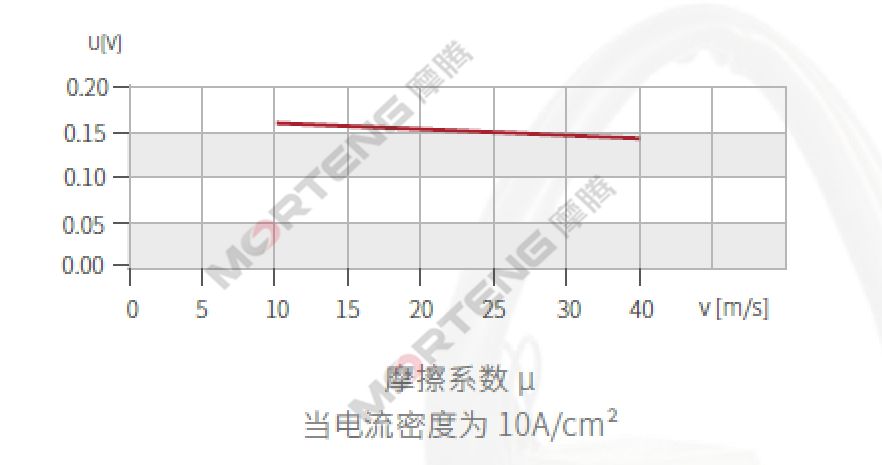

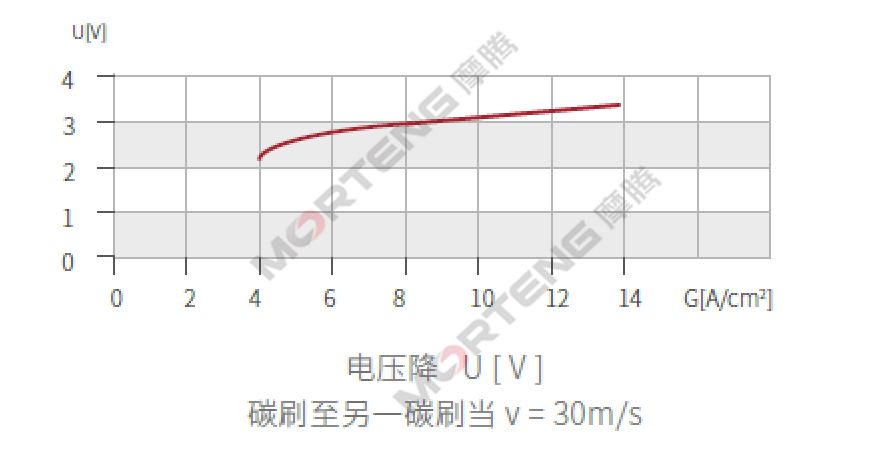

Operational Characteristics

The voltage drop and friction coefficient were measured at below condition: a steel slip ring temperature of 90°Cn a single carbon brush thickness x width = 20*40mm and a carbon brush pressure of 140cN / cm2. Maximum current 96A.

Design & Customized service

As a leading manufacturer of electric carbon brushes and slip ring systems in China, Morteng has accumulated professional technology and rich service experience. We can not only produce standard parts that meet customer requirements according to national and industry standards, but also provide customized products and services in a timely manner according to the customer’s industry and application requirements, and design and manufacture products that satisfy customers. Morteng can fully meet customer needs and provide customers with the perfect solution.

Company introduction

Morteng is a leading manufacturer of carbon brush, brush holder and slip ring assembly over 30 years. We develop, design and manufacture total engineering solutions for generator manufacture; service companies, distributors and global OEMs. We providing our customer with competitive price, high quality, fast lead time product.

Certificate

Since Morteng established in 1998, we has been committed to improving our own product research and development capabilities, improving product quality, offering high-quality service. Because of our firm belief and persistent efforts, we have obtained many qualification certificates and customers’ trust.

Morteng qualified with International certificates:

ISO9001-2018

ISO45001-2018

ISO14001-2015

Warehouse

Morteng has now entered into a stage of diversified and rapid development. It has a large and advanced warehouse, which can ensure efficient distribution and meet the needs of global customers. We have in stock more than 100’000 pcs standard carbon brush and brush holders, more than 500 units slip rings. We can always satisfy our customer’s urgent need.

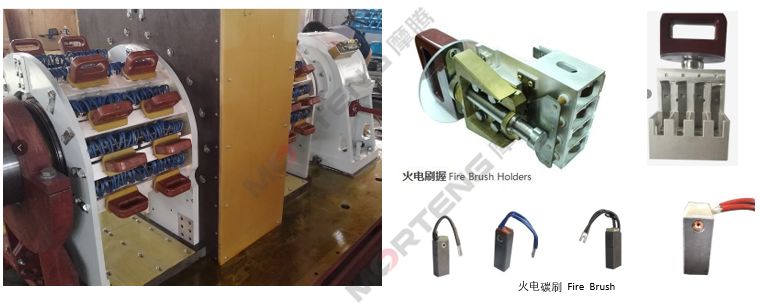

Product detail pictures:

Related Product Guide:

Quality 1st, Honesty as base, Sincere company and mutual profit is our idea, in an effort to create consistently and pursue the excellence for OEM manufacturer Dc Motor Carbon Brush Holder - EH702T Carbon brush for power plant – Morteng , The product will supply to all over the world, such as: Sudan, Venezuela, Morocco, We have sufficient experience in producing products according to samples or drawings. We warmly welcome customers from home and abroad to visit our company, and to cooperate with us for a splendid future together.

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a excellent partner!