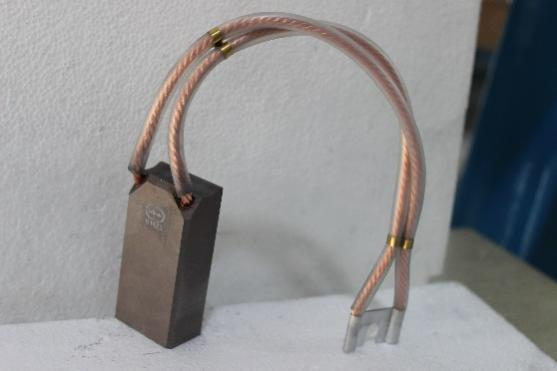

Carbon brushes EH33N for use in steel plant equipment

Detailed Description

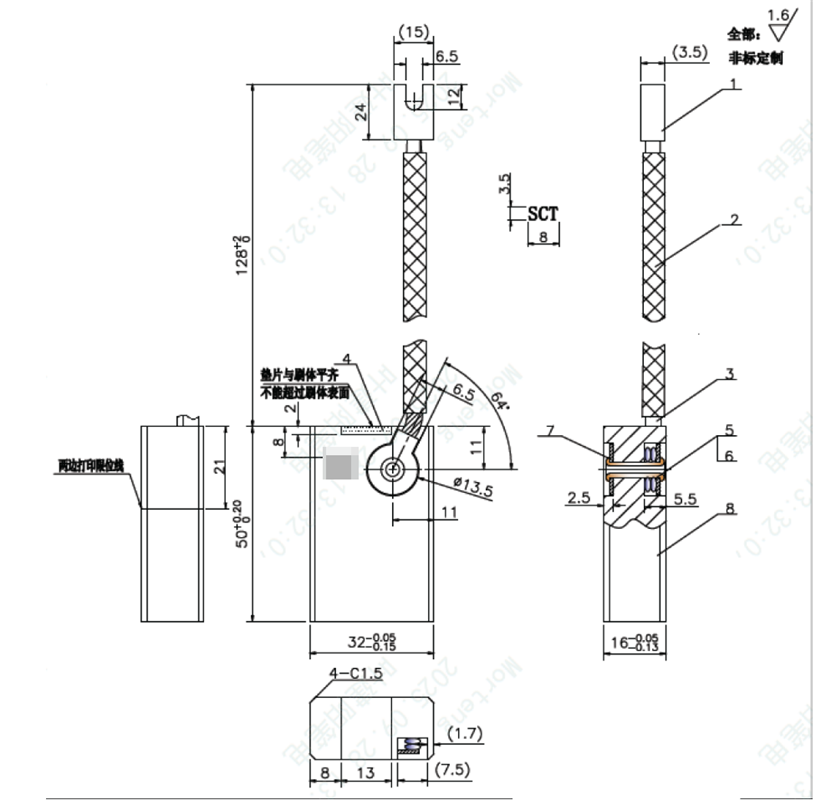

|

Drawing No |

Grade |

A |

B |

C |

D |

E |

|

MDK01-E160320-056-05 |

EH33N |

16 |

32 |

50 |

128 |

6.5 |

Non-standard customization option

Material and size structure can be customized, the normal carbon brush processing finished products and delivery cycle within one week.

The specific size, function, channel and related parameters of the product shall be subject to the drawings signed and sealed by both parties. The above shall be subject to change without prior notice, and the final interpretation shall be reserved by the Company. Product Training

The Advantages of Morteng's EH33N Carbon Brush

Morteng's EH33N carbon brush stands out as a premium choice for electrical equipment, boasting multiple performance advantages. Crafted with selected high-grade materials and advanced manufacturing processes aligned with JB/T standards, it delivers exceptional durability and reliability.

Its wear resistance is remarkable, thanks to optimized material composition that minimizes abrasion during operation, significantly extending service life while protecting commutators from damage. The brush excels in electrical conductivity, maintaining stable current transmission with minimal energy loss and effectively suppressing sparks, ensuring safe operation.

With inherent self-lubricating properties and a low friction coefficient, it enables smooth sliding contact, reducing noise and vibration for quiet, steady equipment performance. It also demonstrates strong thermal stability, withstanding high temperatures without structural degradation, making it suitable for demanding industrial environments.

Backed by Morteng's quality assurance and certifications, the EH33N ensures long-term, low-maintenance operation, making it ideal for motors in automation, manufacturing, and power generation.