Carbon brushes are sliding contact parts in motors or generators that transfer current from stationary parts to rotating parts. In DC motors, carbon brushes could reach spark-free commutation. Morteng carbon brushes are all independently developed by its R&D team, with good wearing, excellent lubricity, stable performance. Our carbon brushes can be designed and customized to meet the requirements of various fields and working conditions. Our carbon brushes are suitable for wind power, thermal power, hydropower, steel, mining, cable, construction machinery, paper, cement, electroplating, rail transit and other fields.

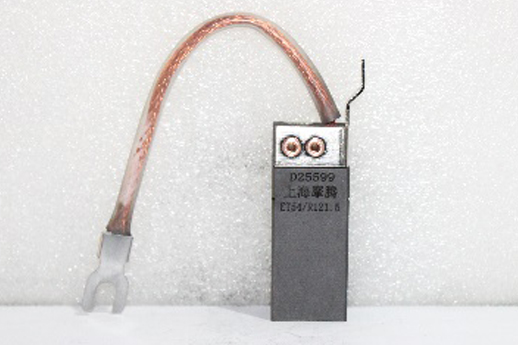

A carbon brush can be consist of:

One or more graphite blocks

One or more wires/terminals

A carbon brush is very important in the motor. In order to fully exploit its role, we need to check three main aspects:

Parameters:

Mechanical parameters

Electrical parameters

Physical and chemical (environmental) parameters

By combining the technical data provided by the customer with the above parameters, our experts can select the most suitable carbon brush material to meet the customer's application.

Our team of experts will also advise the customer on how to optimize the motor parameters to improve the motor's operating quality and maintenance procedures. Through the joint efforts of both parties, the customer's equipment will be improved in performance and service life will be extended.

Morteng brush feature:

Through the unique formula to achieve reliable performance

Stable oxide film forming ability, low friction.

More spark retarding ability, to achieve a smaller carbon brush abrasion.

Smaller carbon brush wear, achieve more stable performance

Why choose us?

Rich carbon brush manufacturing and application experience

Advanced research and development and design capabilities

Expert team of technical and application support, adapt to various complicated working environment, customized according to customer's specific requirements

Better and overall solution, less commutator wear and damage

Lower motor repair rate

Post time: Aug-30-2022