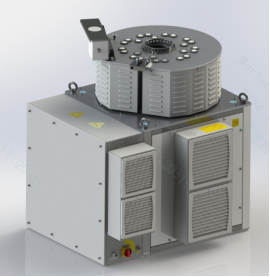

The Morteng yaw slip ring stands as a critical and irreplaceable electrical component in modern wind turbines, strategically installed at the precise junction where the nacelle connects to the tower—a dynamic interface subjected to constant rotational movement during turbine operation. Its core function is to effectively eliminate the inherent risk of twisting, abrasion, and eventual breaking of power cables and control cables routed inside the fixed tower, which would otherwise occur as the nacelle rotates horizontally (yaws) to track wind direction.

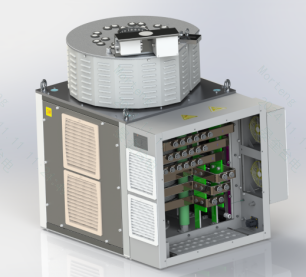

Through advanced structural design and high-precision manufacturing, the slip ring achieves ultra-stable sliding contact between its stationary and rotating components, typically featuring precious metal contacts or carbon brushes paired with durable conductive rings. This specialized contact mechanism enables it to establish a seamless 360° continuous rotating channel for both electrical energy and control signals, bridging the nacelle (rotating side, where the generator, gearbox, and control unit are housed) and the tower (fixed side, which secures the cables leading to the power grid).

Beyond mere connectivity, this transmission channel is engineered to maintain consistent performance under harsh operating conditions—including extreme temperatures, humidity, dust, and vibration commonly encountered in wind farm environments. It ensures that the high-voltage electrical energy generated by the turbine’s generator, as well as the low-voltage control signals (such as those for yaw control, pitch adjustment, and operational monitoring), are transmitted continuously, stably, and reliably to the on-site power conversion system and ultimately to the national power grid.

Simultaneously, by eliminating cable torsion constraints, the Morteng yaw slip ring empowers the turbine to freely yaw and precisely align with changing wind directions in real time. This not only maximizes wind energy capture efficiency but also reduces mechanical stress on the turbine structure, contributing to prolonged operational lifespan, lower maintenance costs, and enhanced overall reliability of the wind power system. As a vital link between the rotating and fixed parts of the turbine, it directly impacts the safety, efficiency, and uninterrupted operation of the entire wind energy installation.

Post time: Nov-04-2025