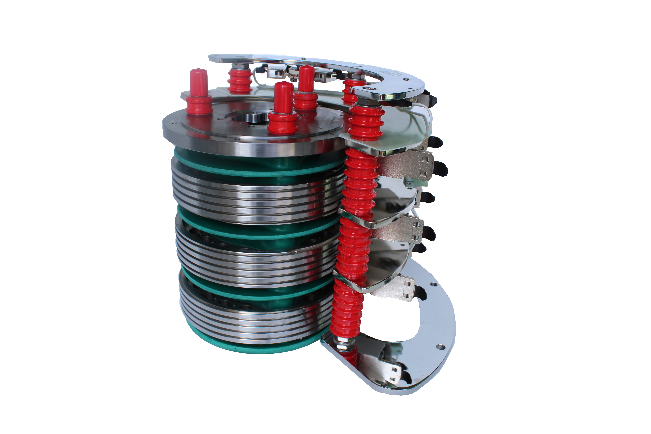

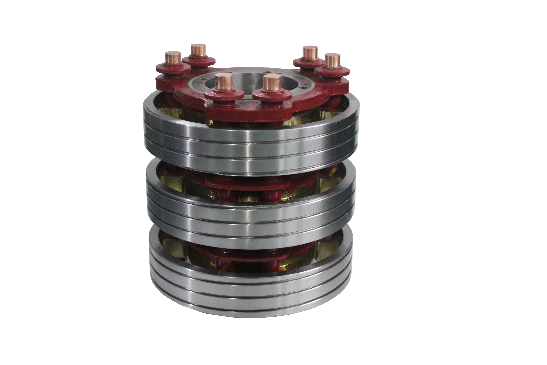

Morteng wind turbine slip rings are key components in wind turbine generators that connect the rotating generator rotor (or pitch/yaw system) to the stationary external circuit, responsible for transmitting power current, control signals, and data. They typically operate in harsh environments and are therefore prone to failure. The following are common faults and their causes:

1. Slip ring surface damage:

Performance: Grooves, scratches, pitting, burn spots, excessive oxidation layer, and peeling coating appear on the ring surface.

Causes:

* Brush hardness is too high or contains hard impurities.

* Poor contact between the brush and the ring surface causes electric arc burn damage.

* Brush particles or other hard particles (dust) entering the friction pair.

* Insufficient wear resistance, conductivity, or corrosion resistance of the ring surface material.

* Overheating due to inadequate cooling.

* Chemical corrosion (salt spray, industrial pollution).

2. Insulation failure:

Performance: Ring to ring short circuit (ring to ring conduction), ring to ground short circuit, decrease in insulation resistance, increase in leakage current, and in severe cases, equipment tripping or damage.

Causes:

* Ageing, cracking, and carbonisation of insulation materials (epoxy resin, ceramics, etc.).

* Accumulation of carbon powder, metal dust, oil contamination, or salt on the insulation surface forming conductive pathways.

* Excessively high environmental humidity causing insulation moisture absorption.

* Manufacturing defects (e.g., pores, impurities).

* Overvoltage or lightning strikes.

3. Poor contact and excessive temperature rise:

Performance: Increased contact resistance, decreased transmission efficiency; abnormal local or overall temperature rise (hot spots visible by infrared detection); may cause overheating alarms or even fires.

Causes:

* Insufficient brush pressure or spring failure.

* Insufficient contact area between brush and ring surface (uneven wear, improper installation).

* Oxidation or contamination of the ring surface leading to increased contact resistance.

* Loose connection bolts.

* Overload operation.

* Blocked heat dissipation channels or cooling system failure (e.g., fan stoppage).

Post time: Aug-27-2025