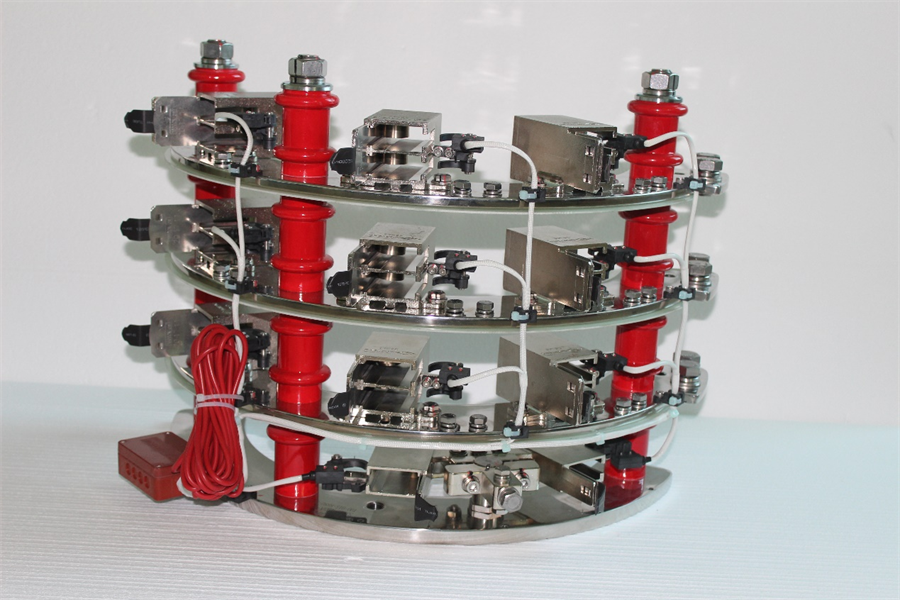

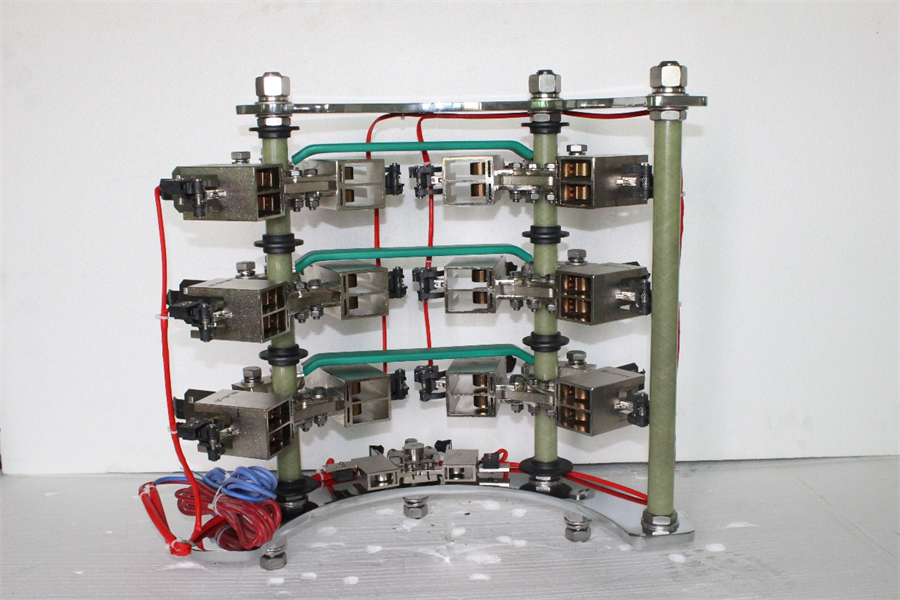

The wind turbine brush holder assembly is a device used in wind turbine generators to secure carbon brushes and facilitate current conduction. It typically consists of the brush holder body, carbon brushes, a spring-loaded pressure mechanism, insulating components, and connecting assemblies. Its primary function is to transmit current from stationary components (such as the electrical control system) to rotating components (such as the generator rotor) through the sliding contact between the carbon brushes and the collector ring (conductive ring), thereby ensuring continuous and stable power supply during the generator's rotation. The brush holder structure must meet requirements for high strength, corrosion resistance, good conductivity, and precise positioning. Common types include tubular, disc spring, and box-type designs, tailored to meet the needs of various wind power applications.

The wind turbine brush holder assembly is a core component of the wind turbine slip ring system, serving as a dynamic conductive bridge:

1. Energy transmission: Transmits the current generated by the rotor windings to the stationary grid via carbon brushes.

2. Signal transmission: Transmits control signals (such as pitch control system signals and sensor data).

3. Grounding protection: Releases shaft currents to prevent bearing electrocorrosion.

The insulation design of the brush holder assembly effectively isolates the electrical connection between rotating and stationary parts, preventing the risk of arcing or leakage. Especially in high-voltage environments (such as the interface between step-up transformers and generators), the high insulation performance of the brush holder ensures the safe operation of the system and the protection of personnel during maintenance. Some wind turbine brush holders are equipped with integrated sensors or lubrication pipe interfaces to monitor slip ring temperature and carbon brush wear, or to supply oil to rotating parts. These smart brush holders not only conduct electricity, but also provide real-time feedback on equipment health data, providing key information for preventive maintenance.

Post time: Jun-26-2025